O-Rings

O-RINGS

American & Metric Sized

O-Rings Made Of Aflas Or Viton Are Problem Solvers For Chemical And High Temperatures Applications.Often Used In Applications Such As Chemical Or High Temperature Aflas And Vition Are Great Solutions. For FDA Grade Applications We Offer Multiple Choices. Common Oil Applications Require Nitrile Or Buna-N O-Rings. Air Or Water Can Sealed With Buna-N, EPDM, Silicone, Neoprene, Or Nitrile. Each Elastomeric Type Has It’s Own Advantages And Cost Factors Attached To It. American Seal & Packing Specializes In Proving The Best Choice For Your Application. Where One Material Has Failed We Can Recommend A Better Suited O-Ring Replacement. Aflas For Example Has A Higher Temperature Range Of 446 F. Than Viton. Viton A Or B Grades Can’t Hold Up To The Same Service As Aflas In Many Applications.

The Importance Of Choosing The Correct O-Ring For An Application

O-Rings Are Sealing Devices Designed To Prevent Leakage During The Process Of Transferring Fluids. Ensuring An Effective Seal With No Leakage Is An O-Rings Main Purpose. If A User Purchases The Wrong Sealing Device, This May Be Disastrous In An Industry Where Leaks Could Lead To Accidents Or Cause Harm To The People Working There. The Staff At American Seal And Packing Have The Expertise And Knowledge To Guide You Through This Detail-Oriented Process. The Main Difference In O-Rings Stem From The Material They Are Composed Of. This Characteristic Will Determine Which O-Ring You Will Need For The Desired Application. When Choosing The Material For Your Application, It Is Important To Consider The Following Parameters: Size, Temperature, Application, Media, Pressure, And Speed (If The Application Is Dynamic).

How an O-Ring Functions

O-Rings used in Chemical Applications:

· Aflas

· FKM / FFKM

· EPTFE

· FEP Encapsulated

· Neoprene

· PTFE

· Viton

· Kalrez / Chemrez / Ameri-rez

An O-Ring functions as a seal through the mechanical deformation of the elastomeric compound by mating metal surfaces. This creates a condition of “zero” clearance which blocks the liquid or gas being sealed. The pressure which causes the O-Ring to move is supplied by mechanical pressure or “Squeeze” generated by proper gland design, material selection, and by the system pressure transmitted by the fluid itself.

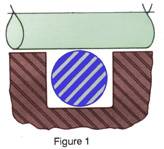

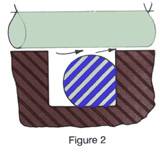

Figure 1 shows an O-Ring IMPROPERLY used. As installed, it is not deformed but retains it s natural round shape. With the applicaiton of pressure as in Figure 2, the O-Ring is likely to deform (as part of its design characteristic) or open a leakage path.

|

|

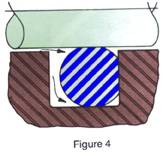

Figure 4 now shows the action of this properly installed O-Ring when pressure is applied. Since both the inner and outer walls are in firm contact with the O-Ring material, the pressure tends to force it along its groove. Engineered to deform, the rubber compound flows up to the passage, completely sealing it against leakage. The higher the pressure trying to leak past, the tighter the seal that is thus formed. Upon release of the pressure, the resiliency of the rubber compound results in the O-Ring returning to its natural round form, undamaged and ready for similar cycles.

By this fundamental explanation, the criteria of design are clearly visible. The initial “diametral squeeze” is vitally important. An initial “diametral squeeze” of 10% results in a flat sealing surface of about 40 to 45% of the initial cross-section area of the O-Ring AT ZERO PRESSURE. Thus, at zero or very low pressures, the natural resiliency of the rubber compound provides the seal. It follows that very low pressure sealing may be improved by increased “diametral squeeze” (but note that such increased squeeze may adversely affect dynamic sealing at higher pressures).

The “diametral squeeze” induces a frictional force between the O-Ring and the walls of the sealed passage that tend to hold the O-Ring in “neutral” position. Until the forces applied are sufficient to either overcome the frictional force or deform the rubber compound, the O-Ring will retain its initially deformed shape and will seal purely by diametral pressure.

|

|

When break-out force is applied, the O-Ring will slide or roll in the direction of force applied until it contacts the end of the groove. From this point on, further pressure or force can only result in deformation of the O-Ring into tighter contact with the inner wall, the groove end and the outer wall.

The O-Ring will initially deform into a “D” shape. This normal deformation will increase the surface contact area to 70 to 80 percent of the initial cross-section. Thus, the contact area of sealing under pressure is roughly twice the area of contact of the original zero-pressure seal resulting from diametral squeeze. It will be apparent from the foregoing that the O-Ring will seal in either pressure direction.

Figure 5 shows the extreme case of deformation just before failure. Note that a small portion of the rubber material has been forced into the small clearance beyond the groove. Assuming the rubber has reached its limit of flow under pressure, further increase of force will result in failure by shear or extrusion as shown in Figure 6. The clearance allowed will bear a direct relation to the force causing failure.

|

|

O-rings, gaskets and seals

Seal SpecialistsAS&P supplies a wide range of orings, cuts gaskets, distributes a wide range of mechanical seals, repairs mechanical seals, stocks sheet gasket material & pump and valve packing braided packing.

Stocking and representing quality lines like AS&P, Durlon, Lamons, Thermoseal, Grafoil, AST, Vulcan, and Latty.

Encapsulated O-Rings

Are all rubber compounds the same?

Rubber compounds vary greatly depending on the source. Being aware of this, especially in today’s market is important. It’s not uncommon that a purchasing agent will search for o-rings by the primary rubber in an o-ring. To really understand how this can be a problem you must understand that because an o-ring is labeled EPDM (or Nitrile, Silicone, Buna, etc), does not mean the o-ring is all EPDM. It’s not! Orings are made of rubber compounds that are blended elastomers. An EPDM oring from one manufacturer will not be identical to an EPDM o-ring from another manufacturer. So, EPDM orings ordered from different manufacturers can perform differently. If your application is on the edge of the envelope, the difference in compounds can be the cause of failure. The same applies to all generic names (Neoprene, FKM, PTFE, etc.). Brand names such as Viton A, Viton B, Kalrez, Teflon, Chemraz will however be consistent since the same compound is being used.

Specific compounds will differ the chemical resistance, temperature resistance, compression set, compression resistance, recovery, swell, resistance to rapid gas decompression, and color.

If you have a compound number we can often supply a specific compound from a specific factory such as Parker, Parko, etc.

Get In Touch

(888) 654-SEAL

Location:

1537 E. McFadden Ave-A

Santa Ana, CA. 92705

sales@americansealandpacking.com

Technical Support:

technicalsupport@usseal.com

Mon: 7:30am - 5pm

Tue: 7:30am - 5pm

Wed: 7:30am - 5pm

Thur: 7:30am - 5pm

Fri: 7:30am - 5pm

Sat: Closed

Sun: Closed